In-house energy generation pays off: The high-performance Kombi Power System supports you as a reliable partner at the location of your choice. Stay independent from rising energy prices and cover your individual energy needs in a cost-saving and climate-neutral way.

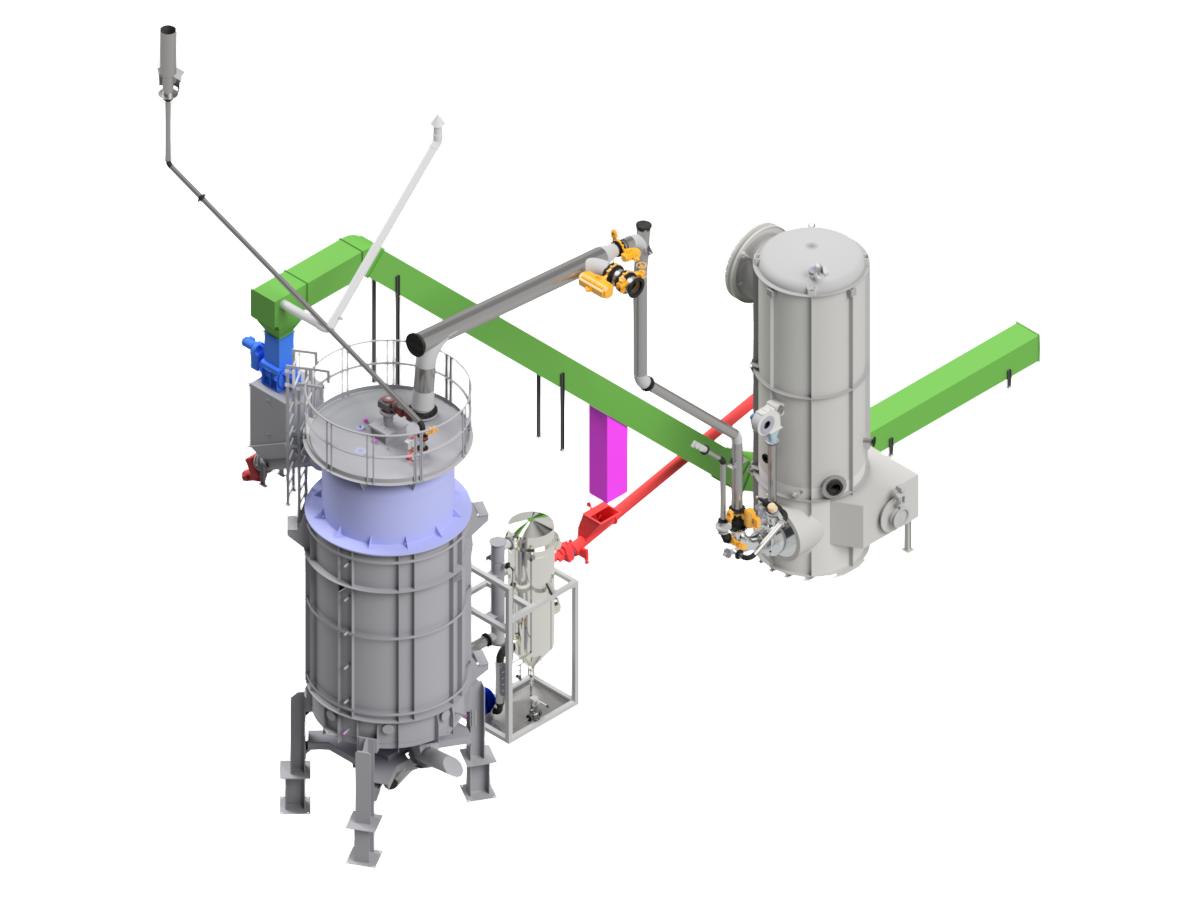

The functionality of the Kombi Power Systems

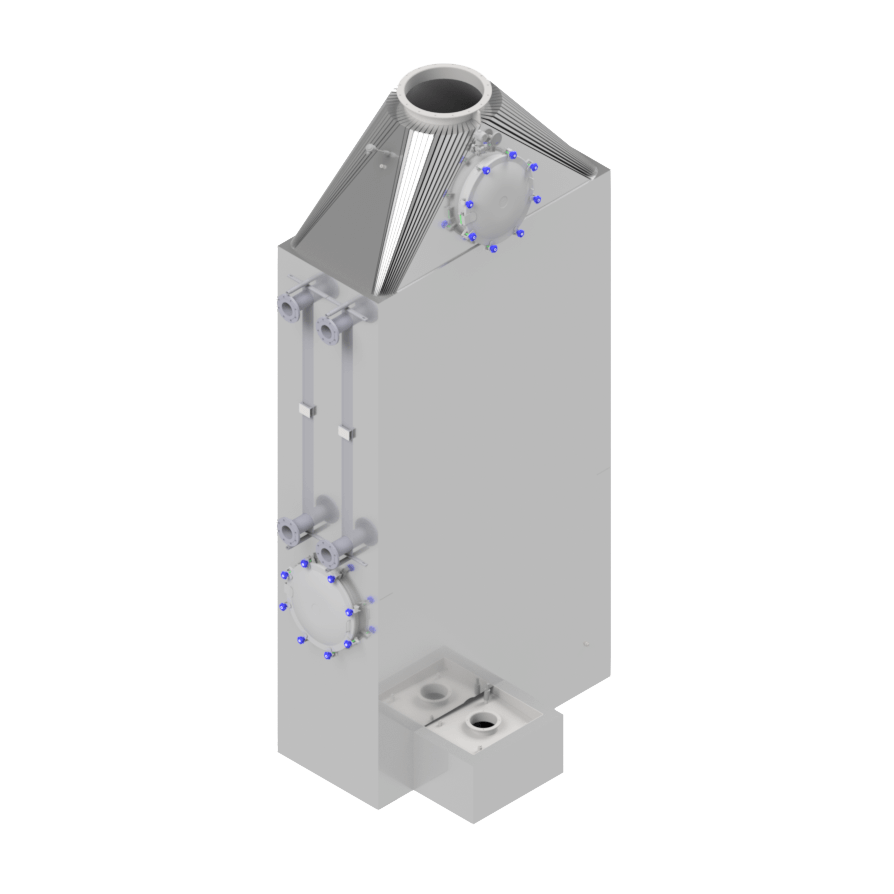

The heart of our plant is the updraft gasifier. In a special combustion chamber, the generated raw gas is burned cleanly and efficiently in startup and shutdown mode as well as in pure heat mode. The addition of supplementary modules can be customized to meet your individual energy requirements.

Fuel loading

Combustion chamber

Updraft gasifier

Choose the energy Combination that suits your needs best:

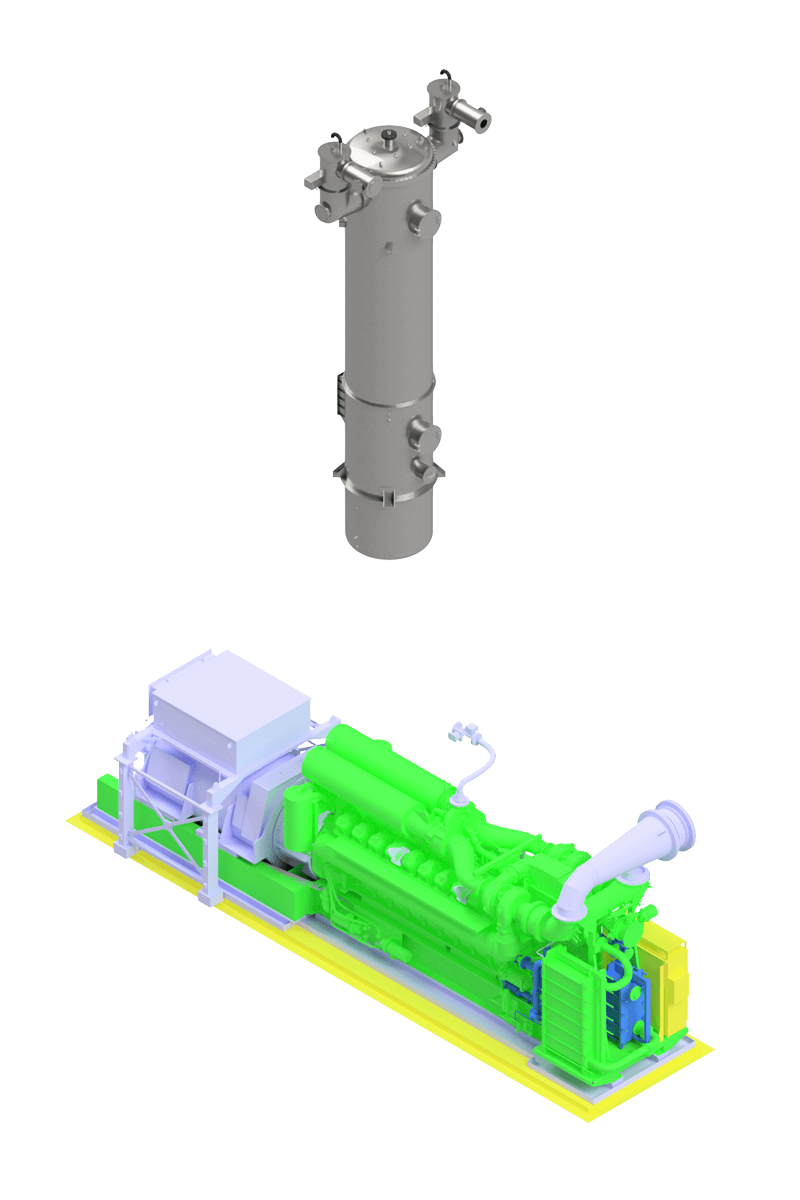

cogeneration unit

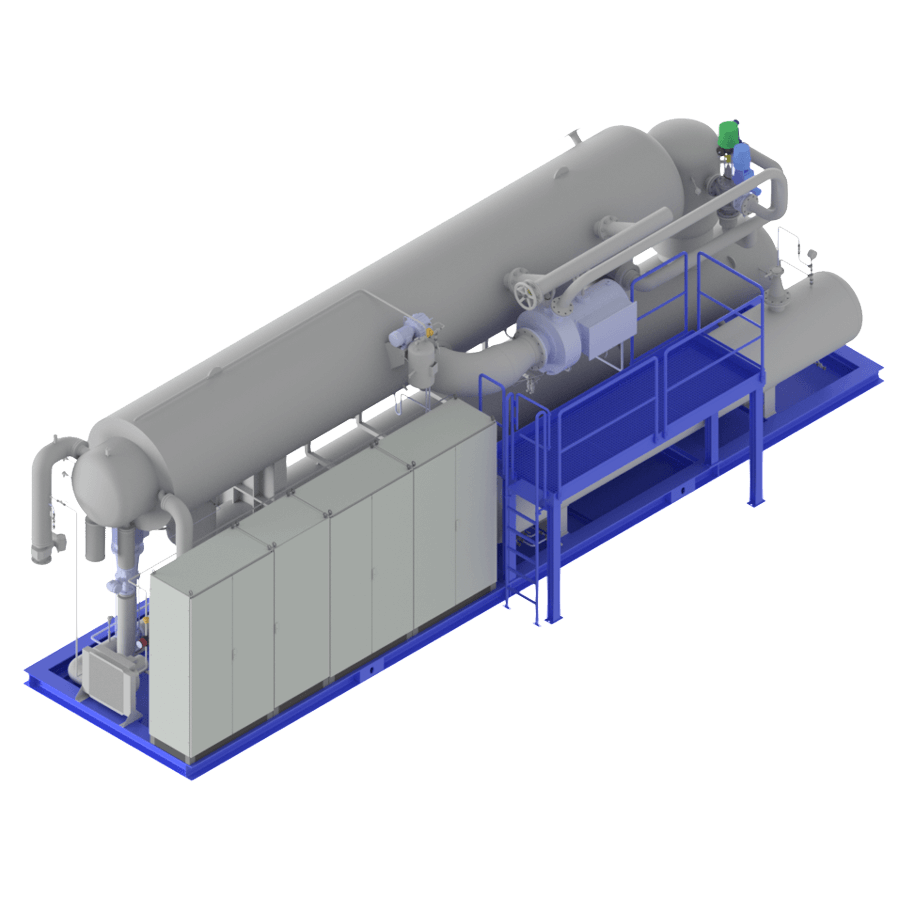

Kombi Power System with cogeneration unit

If the system is to be combined with a cogeneration unit, raw gas is cooled and filtered in 2 stages before entering the gas engine. The cooler and filter are largely maintenance-free.

The resulting bio-oil (pyrolysis oil) can then be used in the combustion chamber to generate heat or can be dispensed as a base material for fuel production.

- Electricity

- Bio oil

- Synthesis gas

- Heat

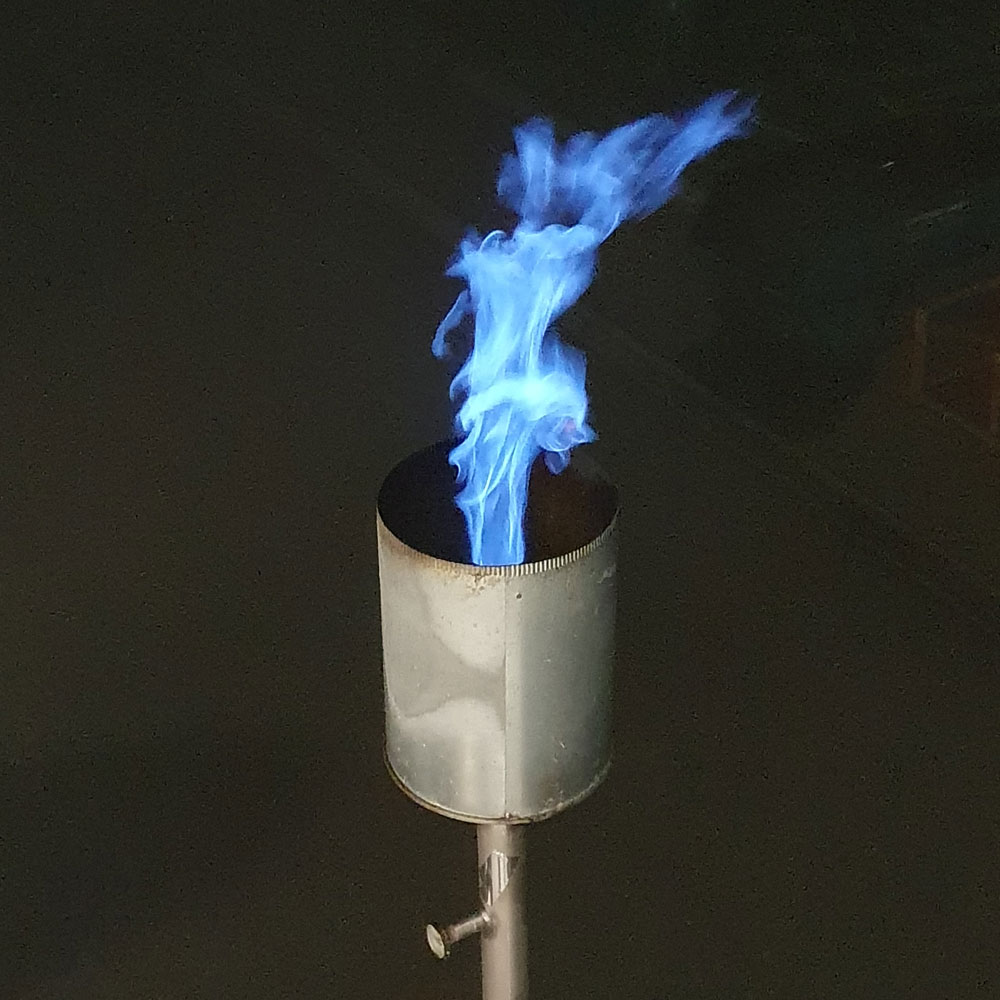

Process gas as the energy of the future

Fossil fuels are still popular energy sources for heat supply. Looking for environmentally friendly alternatives to natural gas, fuel oil or pulverized lignite, process gas offers a high-quality solution.

The product obtained from the updraft gasifier is in no way inferior to conservative raw materials; quite the contrary: You gain a significantly better environmental balance while maintaining the same output.

Other possibilities for process gas utilization:

– Industrial furnaces

– Hydrogen production

– fuel production

– Biomethane

- Synthesis gas

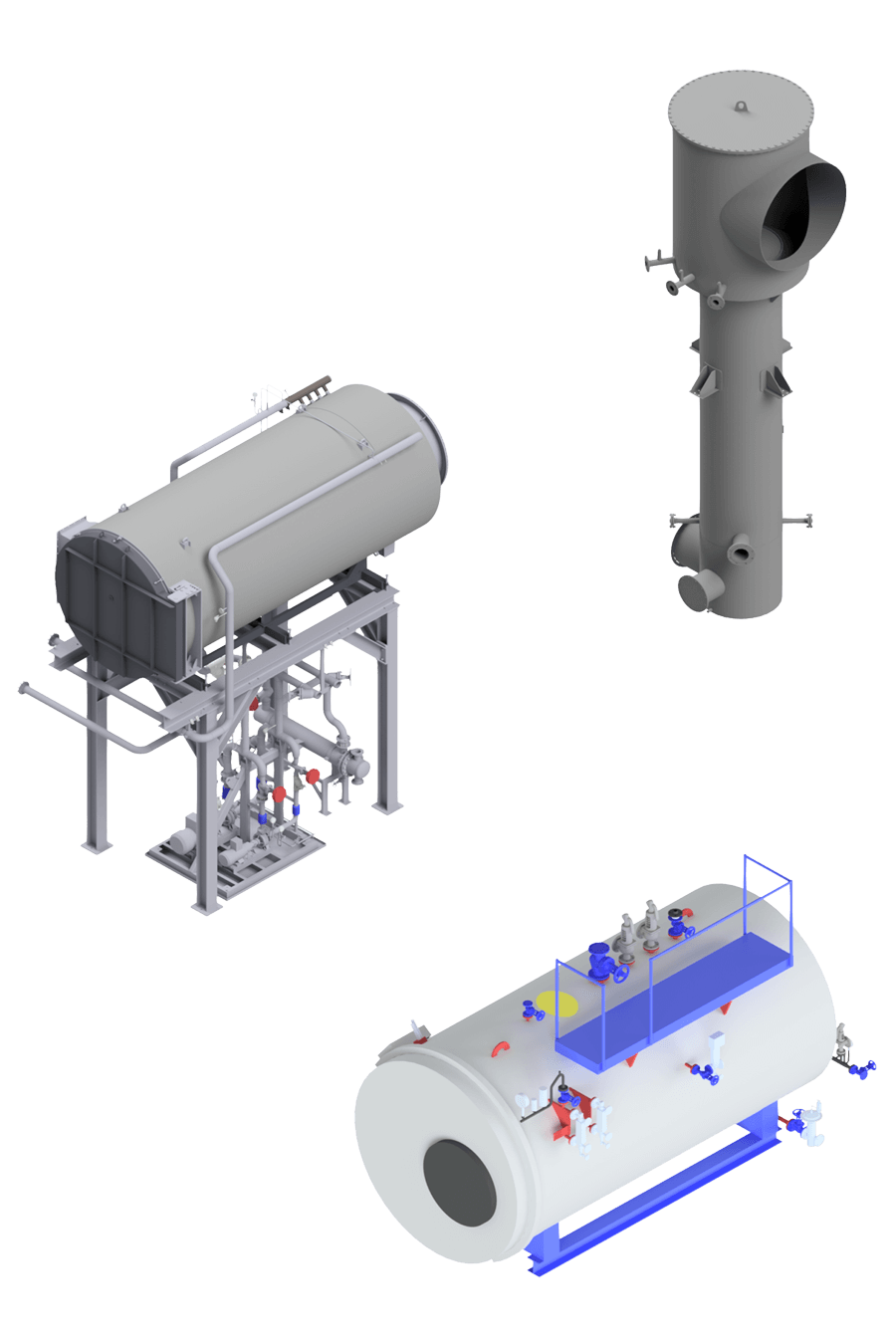

Individual heating solutions

To make optimum use of the heat coming from the combustion chamber, various heating solutions are available depending on the requirements.

Hot water

Hot water boiler for flow temperatures up to 135°C.

Steam

Steam boiler with feedwater preheater for highest efficiencies up to 30 bar.

Thermal oil heater

Thermal oil heater with economizer for flow temperatures up to 315°C.

- Heat

- Steam

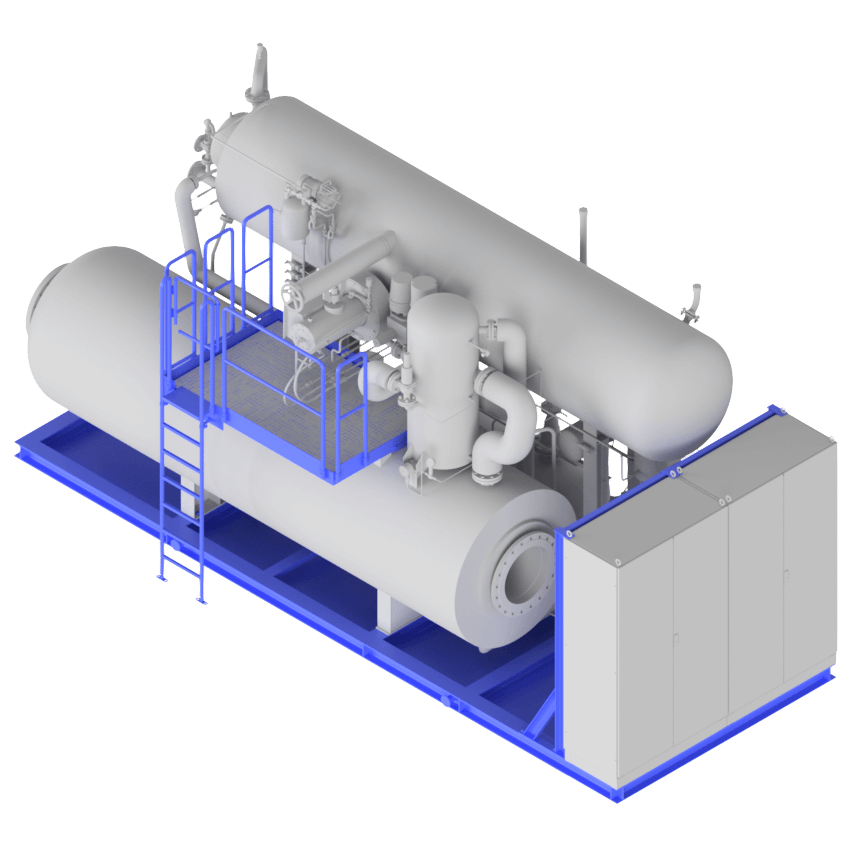

Using thermal oil efficiently

For coupled power and heat generation, a thermal oil heater can be used in combination with a thermal oil ORC system.

- Electricity

- Heat

Using flue gas efficiently

In a direct evaporator ORC plant, flue gas circulation can be used to utilize the clean flue gas recovered from the combustion chamber for coupled power and heat generation.

Alternatively, low-temperature heat (40/55°C) can be transformed into high-temperature heat (80/95°C) in a high-temperature absorption heat pump.

- Electricity

- Heat

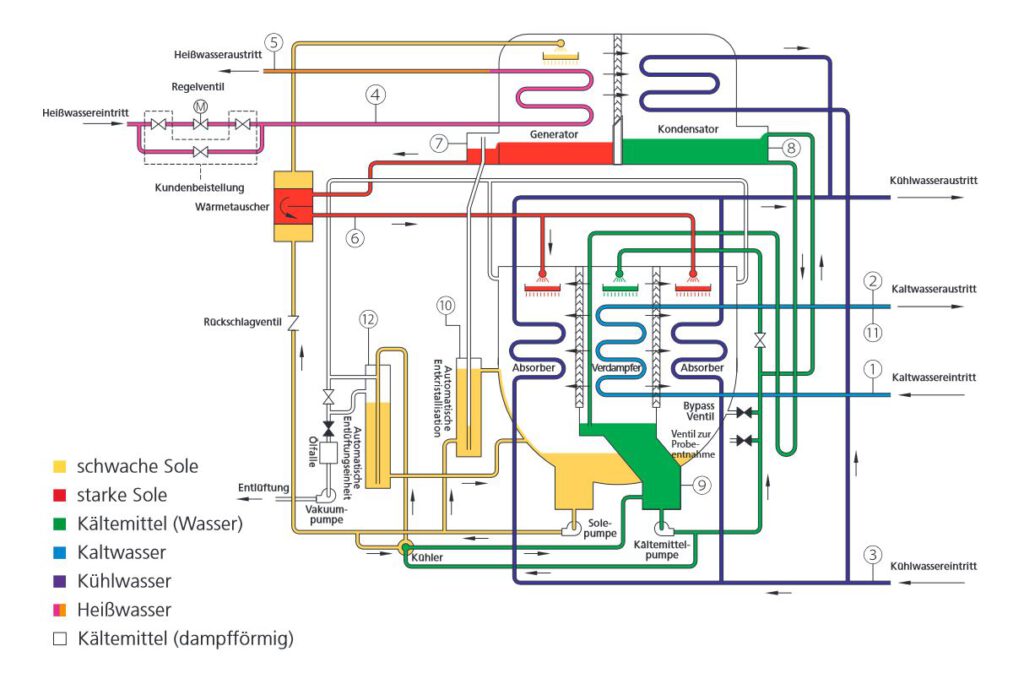

Absorption chiller - Generating cryogenic energy Through heat

The waste heat from the cogeneration unit is ideal for generating cryogenic energy. An absorption chiller generates cold water that can be used as process cooling or for climate control.

The following diagram illustrates the exact process.

- Cryogenic Energy

Maximum efficiency right to the end

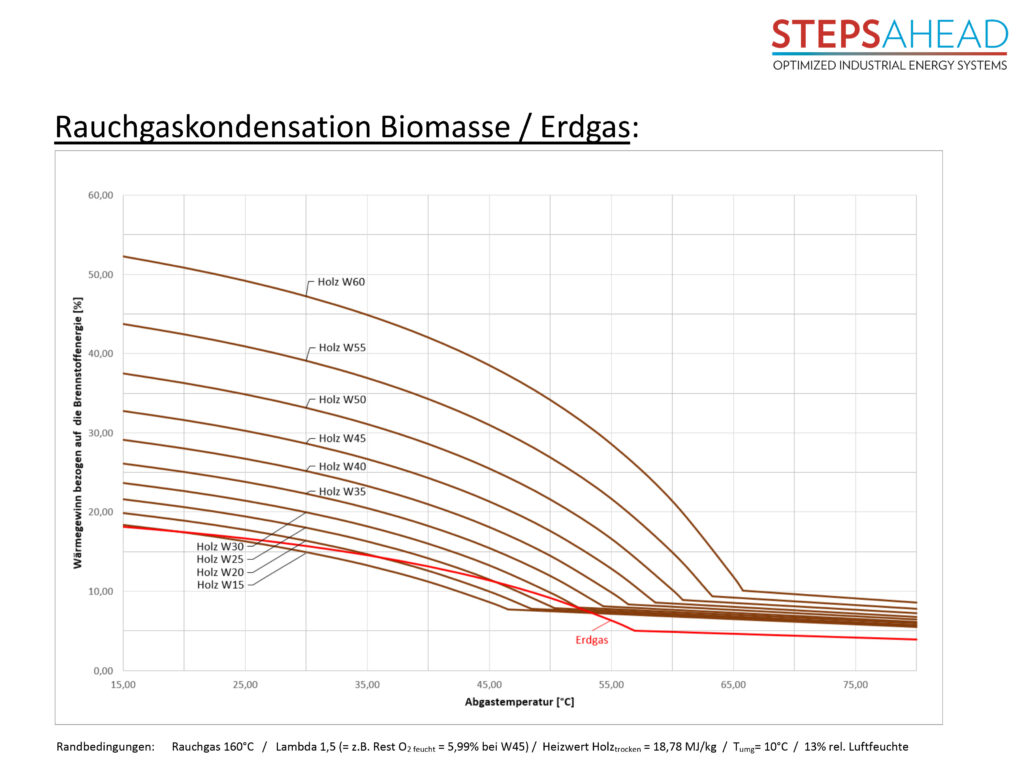

Various boiler types with economisers are used by default for flue gas utilisation.

In addition, a flue gas condensation system can be installed. This is used for maximum exhaust gas heat recovery with additional low temperature heat utilization.

The flue gases are characterized by a high volume of water vapor. By cooling this flue gas moisture and condensing it, up to 40% of the fuel heat can be recovered.

The following applies:

The lower the return temperature (or at least a partial flow thereof), the higher the heat recovery.

- Heat

Possible Use cases:

- Energy-intensive commercial enterprises such as:

- Joineries

- Dairies

- Breweries

- Greenhouses

- Sawmills and lumbermills

- Other possible applications:

- Industry with process heat demand

- Local and district heating networks

- Small communities and cities

Technical data:

-

Electric Power 260-1970 kW

-

Gasifier Size 2.0-2x4.5 MW

-

Fuel thermal output 1187-6982 kW

-

Fuel demand 1,7-10 Sm³/h

-

Th. output waste heat boiler 383-1752 kW

-

Th. output engine cooling 94-993 kW

-

Th. output gas cooling 136-1100 kW

-

Optional: flue gas condensation 226-1332 kW

-

Total heat capacity HT 523-2744 kW

-

Total heat capacity HT+LT 885-5177 kW

Why choose Kombi Power System?

Fuel

- Pre-drying the fuel is not necessary

- Robust conveying technology allows for large and lumpy fuels

- Fuel diversity: waste wood, forest chips, landscape conservation wood, screen residues from composting plants, bark, etc.

- Continuous expansion of the fuel range as a result of tests at our pilot plant

Efficiency

- The modular design allows maximum flexibility while maintaining the highest possible efficiency.

- Fuel burnout is total, leaving clean ash behind.

- High degree of cold gas utilization: The gas outlet temperature is only 75° C.

- The Kombi Power System impresses with the best possible heat utilization concept

- High efficiency due to the counterflow principle

Scalability

- The Kombi Power System is capable of partial load and can be adjusted during operation.

- The plant can be expanded and adapted further along the line.

- Due to the counterflow principle, upscaling and downscaling can be realized easily.

What lies ahead

The energy issue that we face in the coming years is more complex than ever. This makes it all the more important to understand formative trends in our industry and provide innovative answers.

By continuously optimizing our system, we can offer a sustainable energy solution with forward-looking prospects.

Alternative fuels

A wide variety of production residues, such as nutshells, make excellent fuels. We are already testing this alternative in our pilot gasifier for use in everyday operations.

Other alternative fuels

- Miscanthus

- Sewage sludge briquettes

- Agricultural residues

- Plastics

- Residues from the food industry

- Low quality wood briquettes

reFuels / Biomass to liquid (btl)

In order to get closer to climate-neutral energy production, we supply the basic material for reFuels and other sustainable fuels. For example, we are investigating the use of bio-oil as a basis for fuel production in a funding project with the FNR.

For example, simple processing steps for the production of fuels for robust marine diesel engines, more complex refinery processes for the production of high-quality fuels, and Fischer-Tropsch syntheses are available.

Hydrogen

A special process enables us to produce particularly reactive raw gas, which is then refined even further. The reactive gas, which consists mainly of water, carbon dioxide and monoxide, methane and hydrogen, enables a hydrogen yield of up to 40%. Through further reforming and final PSA, the hydrogen content can be increased to over 99%.

Bio-methane

In a pilot project, we are researching the possibility of obtaining bio-methane from biomass heating (power) plants that can be used for synthesis processes. In cooperation with the Friedrich-Alexander University (Erlangen-Nuremberg) as well as our cooperation partner prosio engineering, we have set ourselves the task of developing an effective alternative to fossil fuels: "green natural gas".

We expect this project to deliver an innovative technology with great impact and rapid market availability.

Our reference units

You would like to get an idea of our Kombi Power System? Get an overview of our reference projects. We would be more than happy to give you a practical insight into our work on the basis of successfully completed plant designs.

From first contact to finished plant

We support you from the initial contact to the turnkey plant with clearly defined processes and transparent cooperation.

- After your initial inquiry, you provide us with your energy requirements. We will be happy to assist you in determining them if necessary.

- Based on the determined data and the site-specific conditions, we will start planning your individual Kombi Power System.

- In cooperation with our partners, the construction of your system will be implemented.

- After approx. one year of construction, we hand over the turnkey plant and put it into operation.